Stained glass machine

Filling systems allow for the creation of ornamental or thematic decorative compositions of any complexity, including the imitation of stained glass and engraving effects.

DIRECTIONS OF FILLING SYSTEMS

1. Stained glass equipment.

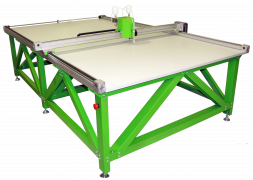

Stained glass machines are designed to create products that imitate classic stained glass. In other words, the machine draws an outline that divides the stained-glass drawing into segments, imitating soldered seams in classical stained glass. This is where the name of such stained glass and the equipment on which they are produced came from – Outline. Their second name is Fill-in stained glasses since the space between contours is then filled with background varnish, with the addition of various pigments, depending on the stained-glass drawing. Outline machines can reproduce a drawing of any complexity, different sizes on regular and satin glass, mirror, plexiglass, and other materials.

All stained-glass machines perform one function - they apply the outline of a stained-glass drawing, but at the same time, there are significant differences between models of outline machines.

Firstly, the size of the working area - the buyer has the opportunity to choose the size of the machine's working area, based on the specifics of the products he produces and also considering the area of the room where the equipment will be located.

Secondly, the speed mode - different machine models have different contour application speeds. Here, the scale of production of the finished product should be considered. For example, to manufacture exclusive designer products with fill-in stained glass, a machine with low speed may suffice, while for a factory producing furniture and interior doors, a stained-glass machine with higher performance is required.

Thirdly, additional machine options - There are models of stained-glass machines equipped with the function of applying an outline to curved surfaces, and curved glass and film cutting.

2. Painting furniture fronts. - AirGraf furniture front paintion equipment significantly simplifies and automates the patina application process. You can apply drawings both to flat parts and parts with relief. The minimum material thickness is 5 mm. An automatic cleaning system makes it easy to change the patina color.

3. Filling systems for dosing silicone, polyurethane, lubricant. One of the priority directions that our company will bring to the market in the near future. Metering materials is required at the stages of vehicle assembly, during furniture or interior items manufacturing. Precision dosing of materials allows you to strictly comply with all production standards and minimize the occurrence of defects during work.

Our machines stand out for their high quality, extended warranty period (2 years), quality service, and high professionalism of our employees. By purchasing equipment from us, you get not just equipment, but full-fledged technology and ready solutions.