СТОЛ ДЛЯ РАСКРОЯ И РЕЗКИ СТЕКЛА "SHERHAN"

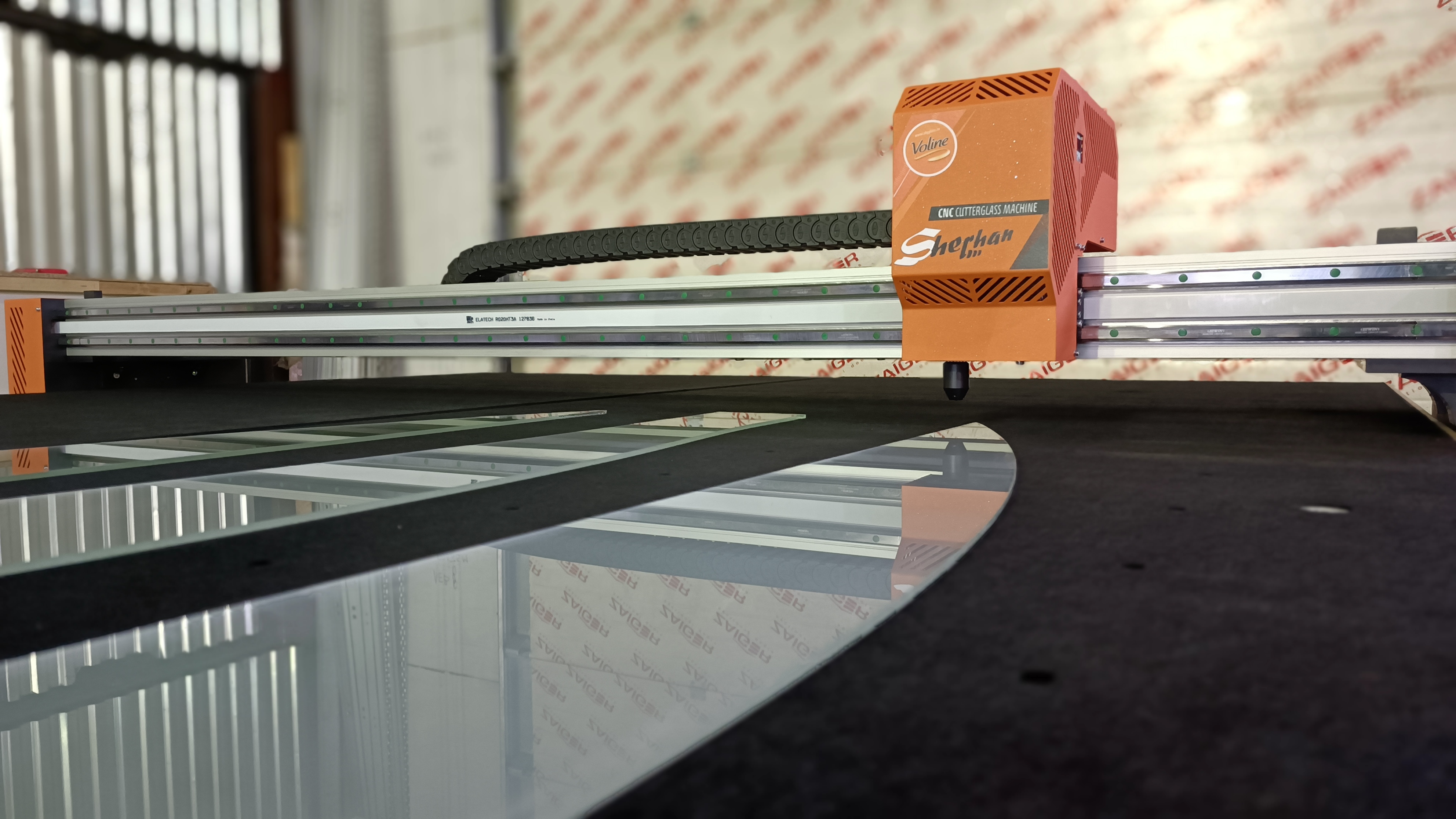

Промышленный ЧПУ станок для резки листового стекла и его разлома - это высокотехнологичное оборудование, предназначенное для автоматизации процессов резки и разлома листового стекла от 2 до 19 мм.

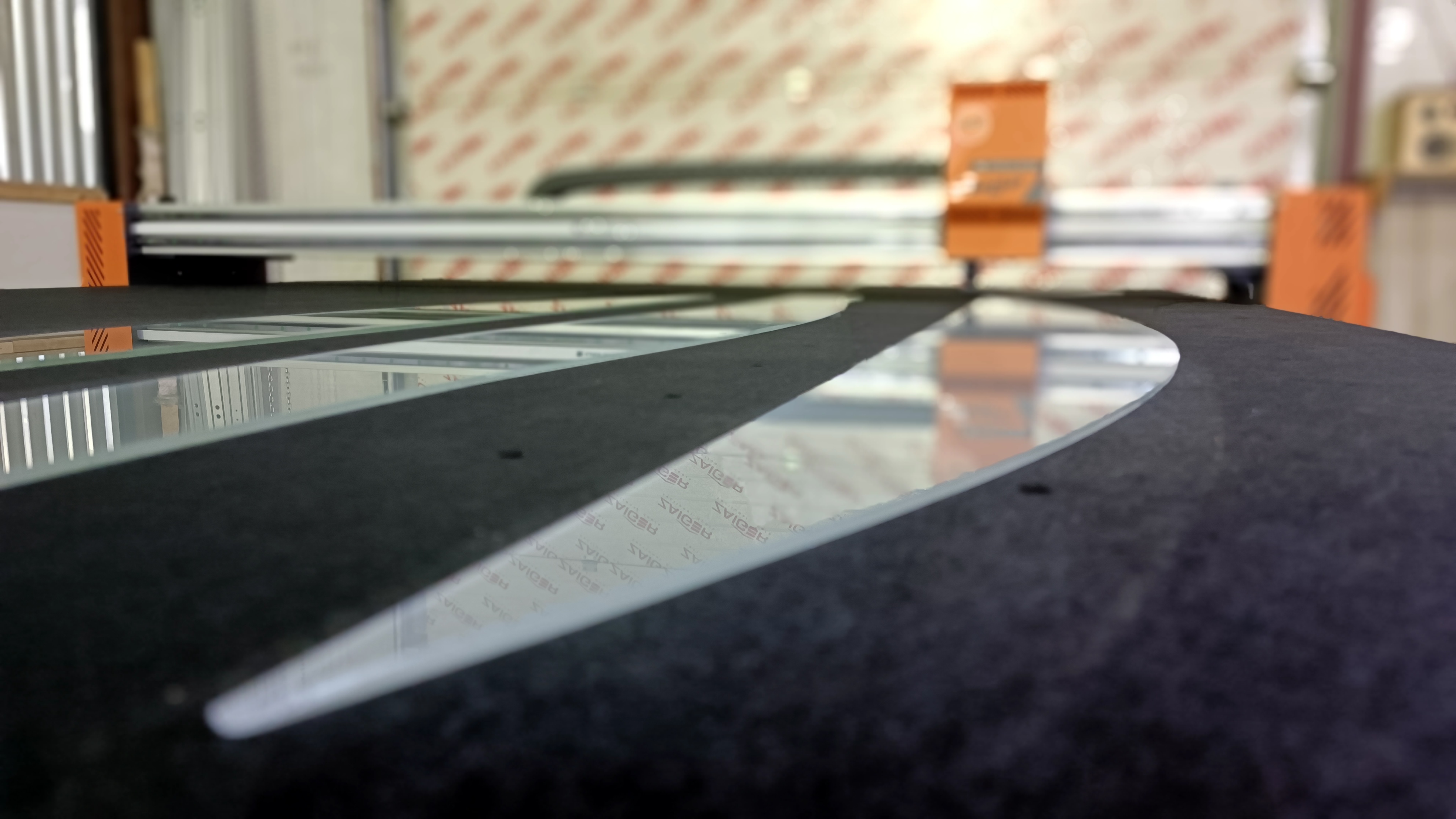

Стол для автоматического раскроя стекла

Стол для автоматического раскроя стекла SHERHAN CM 1828 - это высокотехнологичный станок, который используется для прямолинейного и криволинейного раскроя листового стекла и зеркал.

Устройство оснащено воздушной подушкой и сканированием положения стекла для позиционирования стекла, что обеспечивает высокую точность позиционирования.

В своей работе стол для резки стекла и зеркал обладает высокой стабильностью работы, благодаря металлической сварной конструкции.

Кроме того, использование серводвигателей MITSUBISHI дополнительно повышает точность работы станка.

Рабочая зона станка составляет 1800х2800 мм, что позволяет эффективно использовать его для раскроя различных размеров листового стекла и зеркал.

Рабочая зона 1800х2800 мм

СЕРВОДВИГАТЕЛИ MITSUBISHI

CИСТЕМА ОПТИМИЗАЦИИ

ПРОИЗВОДИТЕЛЬНОСТЬ ДО 100 М/МИН

ТОЧНОСТЬ РЕЗКИ 0,15 ММ

ПРЕИМУЩЕСТВА ЧПУ СТЕКЛОРЕЗА SHERHAN

Тангенциальная поворотная ось

Позволяет увеличить производительность и уменьшить отходы стекла и зеркал в процессе резки

Автоматическая регулировка давления

Автоматическая регулировка давления/подачи жидкости на режущий ролик в зависимости от скорости прохода траектории, а также от требования при прямолинейной и криволинейной резки стекла

Высокоточная механика

Станина выполнена из жесткой сварной рамы. Все детали для станка изготавливаются на ЧПУ станках, что позволяет создать механику с точностью резки до 0,15 мм при скорости в 90 м/ мин на рабочем столе 1700х2800 мм, и до 180 м/мин на столе 2600х3300 мм.

Система оптимизации

Позволяет максимально упростить создание карты раскроя для прямолинейной резки стекла

Воздушная подушка

В комплекте со станком идет мощный вентилятор для подачи воздуха. Он позволяет равномерно распределять на поверхности стола воздуха и образовывает воздушную подушку для уменьшения силы трения при соприкосновении стекла с рабочей поверхностью.

Упоры для позиционирования

Пневматически активируемые упоры позволяют с точностью расположить стекло в нулевую точку станка, не прибегая к дорогой системе сканирования материала

Система разлома стекла

Активируются педалями. Расположена одна по длинной сторону станка, позволяет упростить разлома стекла, толщиной более 8 мм.

Расширенная гарантия

На механические и электрические части станка мы даем 2 года гарантии

ХАРАКТЕРИСТИКИ СТЕКЛОРЕЗА SHERHAN

| Параметры | SHERHAN CM 1828 | SHERHAN CM 2633 |

|---|---|---|

| Рабочая зона | 1800х2800 мм | 2600x3300 мм |

| Рабочая скорость | 90 м/мин | 180 м/мин |

| Минимальная толщина стекла | 2 мм | 2 мм |

| Максимальная толщина стекла | 19 мм | 19 мм |

| Контроль осей | Серводвигатель MITSUBISHI | Серводвигатель MITSUBISHI |

| Точность позиционирования | 0,15 мм | 0,15 мм |

| Точность перемещения | 0,15 мм | 0,15 мм |

| Головка флюгерного типа с пневмоприводом | + | - |

| Тангенциальная поворотная ось | - | + |

| Покрытие стола | Фетровый материал | Фетровый материал |

| Автоматическая подача жидкости в зависимости от скорости резки | + | + |

| Воздушная подушка | + | + |

| Выдвигающиеся упоры | + | Система сканирования |

| Cистема разлома стекла | Опционально | + |

| Передача по оси X | Косозубая рейка шестерня |

Косозубая рейка шестерня |

| Передача по оси Y | Ременная Elatech | Косозубая рейка шестерня |

| Передача по оси Z | Пневматика Camozzi | серводвигатель MITSUBISHI |

| Питание | 380 3Ф 50-60гц | 380 3Ф 50-60гц |

| Поддув воздуха | 6-8 Атм | 6-8 Атм |

| Мощность | 5300 Вт | 8000 Вт |

| Программа управления станком | SkyglassProfi | OptyWay |

| Внешние габариты станка | 2250х3300х1300 мм | 3100х4100х1200 мм |

| Габариты упаковки станка | 2300х3500х1300 мм | 2400х4600х2600 мм |

| Вес станка, нетто | 800 кг | 1800 кг |

| Вес станка, брутто | 900 кг | 2000 кг |

Особенности станка для резки стекла

Станок для резки стекла Sherhan имеет рабочую зону 1800х2800 мм, которая позволяет обрабатывать крупные листы стекла (формата 1605х2550 и 1800х2600 мм).

Производительность резки стекла и зеркал до 90 метров в минуту – это свидетельствует о высокой скорости и эффективности работы станка.

Толщина резки стекла от 2 до 19 мм, что обеспечивает широкий спектр возможностей по работе с разными видами стекла.

Точность резки составляет 0,15 мм – это дает возможность получать высококачественные и точные заготовки из стекла.

Одной из важных особенностей станка является наличие воздушной подушки для легкого перемещения стекла. Это удобно и позволяет снизить нагрузку на оператора при переноске листов стекла на станок.

Станок также оснащен системой разлома стекла по длинной стороне, что значительно упрощает процесс разлома стекла и повышает производительность работы.

Оптический сканер для определения положения стекла на рабочем поле станка обеспечивает точность позиционирования и надежность резки.

Станок оснащен сканированием шаблонов для резки и библиотекой готовых шаблонов, что делает этот станок универсальным и позволяет быстро и качественно выполнять заказы своих клиентов.

Программа оптимизации сокращает время настройки и увеличивает производительность работы станка, обеспечивая рациональное расходование материала и уменьшение отходов при обработке стекла.

Станок для резки стекла Sherhan – это надежное, функциональное и производительное оборудование, которое обеспечивает максимальную точность и качество резки стекла. С помощью этого станка можно обрабатывать самые сложные заказы и получать отличные результаты в работе с любыми видами стекла. Учитывая все следующие преимущества, станок Sherhan - отличное решение для индустрии обработки стекла.